Carbon Fiber Rope Properties

Fiber of over 120 million is available.

Carbon fiber rope properties. In space kevlar fiber has proven that it is strong enough to survive the extreme forces and temperature fluctuations of space travel. Carbon fiber has excellent strength properties. The products are used around the world as central strength members or as components of larger rope and cord structures. Carbon fiber elevator rope rides to the rescue high in the sky steel rope was once the material of choice for elevator function but as buildings exceed 500m in height it s just too heavy.

Here are some more extensive tables for heat conductivity. All high modulus high performance fibers such as. Wikipedia table of thermal conductivity engineering toolbox s table are alternatives i got the figures for thermal property measurement of carbon fiber epoxy composite materials from a dissertation for phd from university of nebraska. The coating is highly resistant to wear and abrasion.

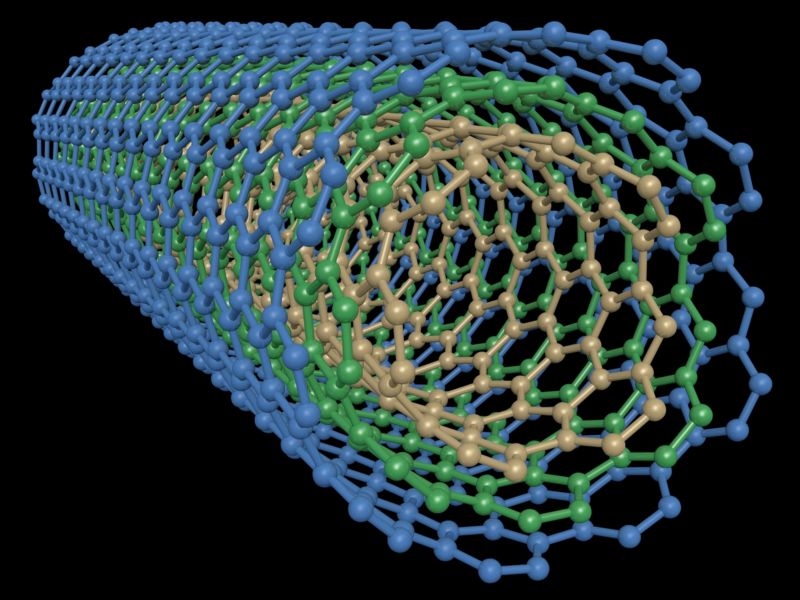

Aramid fiber ropes are also used in the heaviest marine applications e g 6 1 8 156 mm diameter technora with a breaking strain of 3 000 000 lb 13 300 kn. Properties of carbon fiber composites are dependent on the direction and the properties shown above are only valid for one direction typically referred to as the longitudinal direction. They are unaffected by water exhibit some creep under continuous load and are about three times stronger than nylon or polyester of the same weight. Ultra light rope with carbon fiber core surrounded by high friction coating.

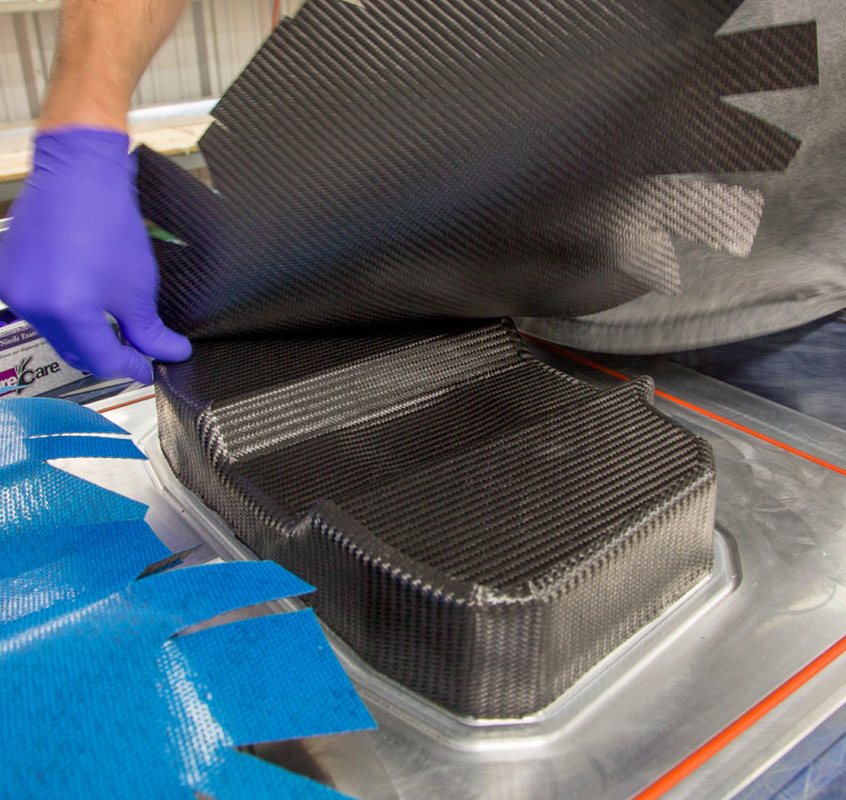

The top countries of suppliers are china bangladesh and vietnam from which the percentage of high strength carbon fiber rope supply is 96 1 and 1. Key benefits of carbon fiber. This data and information shown should only be used for comparison purposes it should not in any way be used for design purposes as actual properties will vary based on many factors including. Raptor resins develops and manufacturers lightweight high strength carbon fiber products for commercial and industrial applications and has pioneered the development of carbon fiber cable rope and string under the fibraplex brand a perfect product when qualities like strength corrosion resistance light weight flexibility stability at extreme temperatures and low stretch are important.

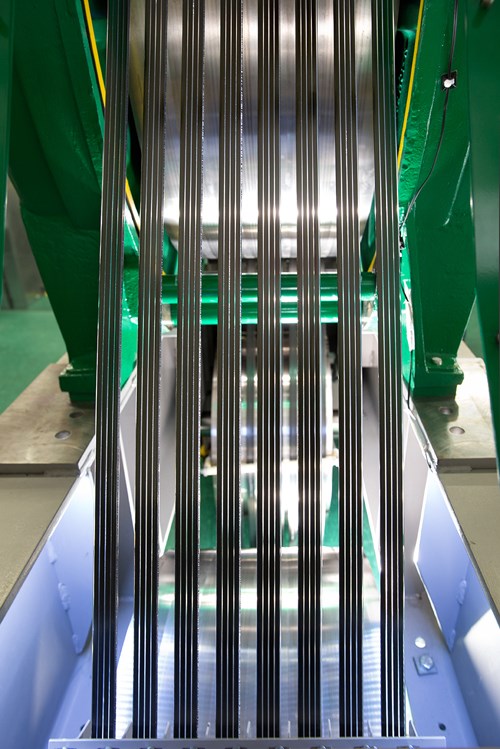

Utilizing fiber line processing capabilities extrusion pultrusion twisting and performance enhancing coatings allow our customers to achieve optimal performance. Low stretch typical cf has tensile modulus of 30 million psi which is the same as steel. Skip to page 128 for the results but have a look at the process. Strength typical cf has a tensile strength of 500 000 psi compared to 100 000 for steel and 5 000 psi for nylon.

Less sensitive to building sway frequencies that can cause elevator downtime during high winds.