Breaking Strain Of Wire Rope Formula

These tests are done by incrementally increasing the load that a rope is expected to carry until the rope breaks.

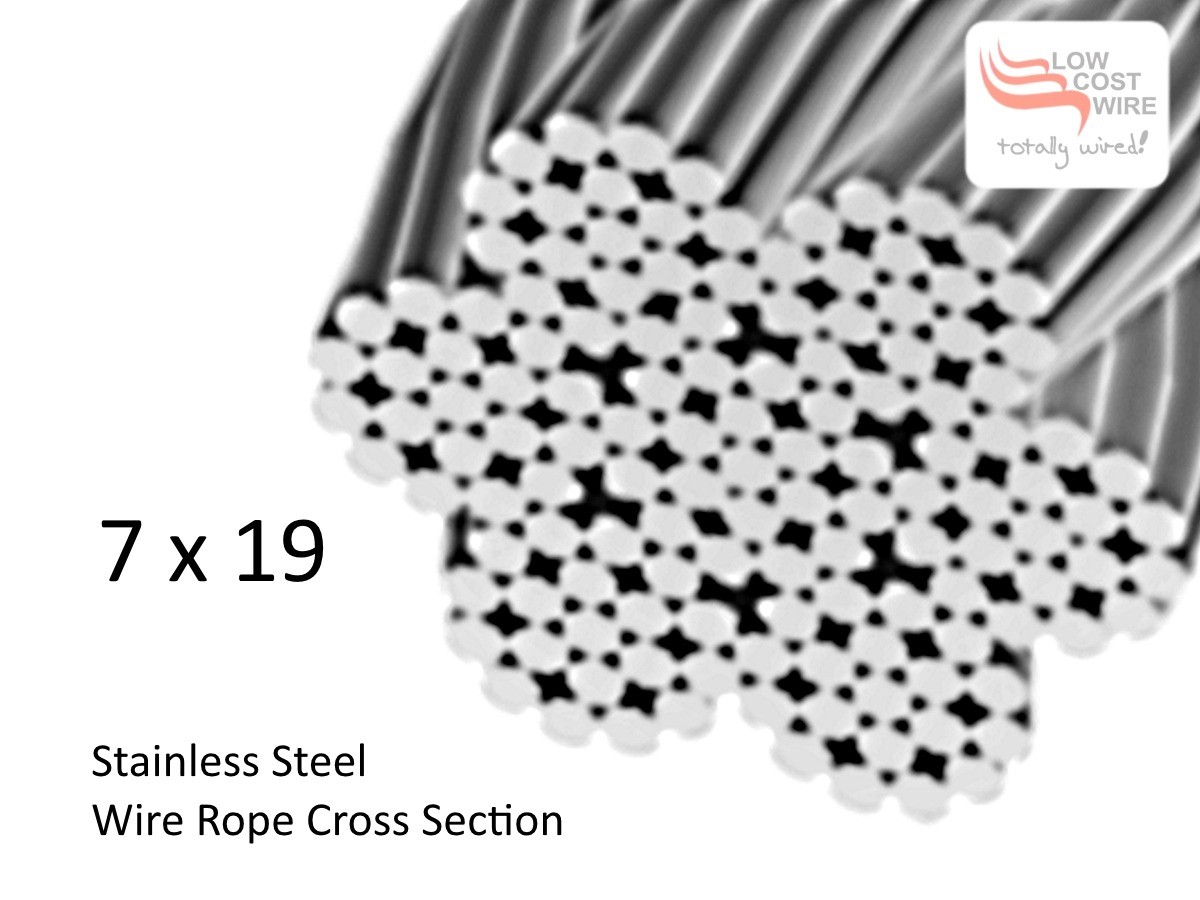

Breaking strain of wire rope formula. It is a common rope in the 6 x 19 clas vlàfdwlrq 6 x 26ws warrington seale a standard 6 x 26ws design pro vides the best rope for a wide range of applications. 6 x37 21d2 tons 500. Wire to most wire rope users 6 x 19 means 6 x 25 filler wire. Divided by sign.

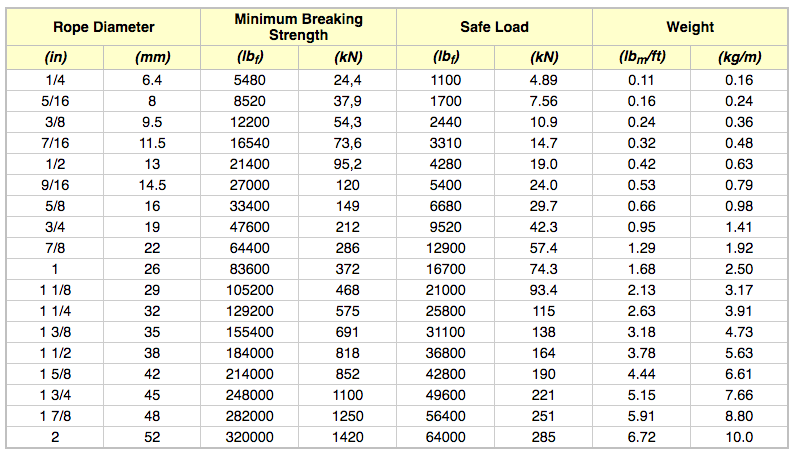

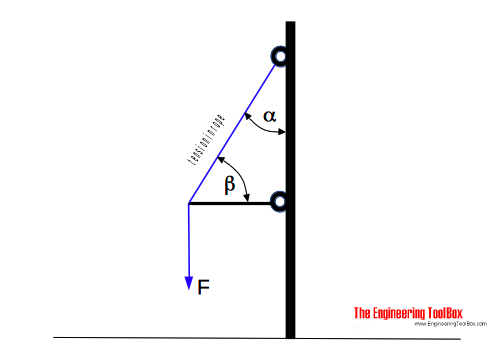

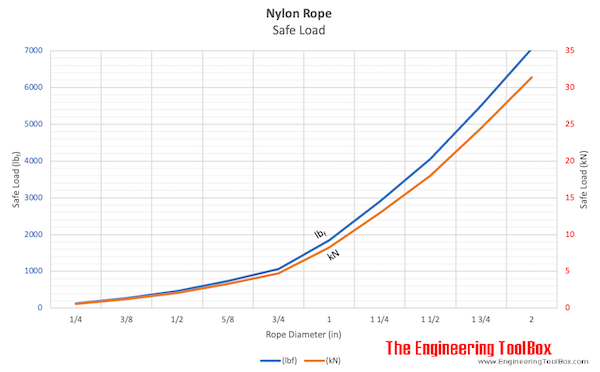

A simple wire rope strength chart can help you keep a close eye on wire rope strengths if find this to be an issue. Miscellaneous engineering related topics like beaufort wind scale ce marking drawing standards and more. Force and tension in rope due to angle reduced load capacity in ropes cables or lines due to angle. Elevator force and power required force and power to lift an elevator.

The result is the safe working load in tons. For example a rope with a 2500kg mbs using a factor of 10 if in use for ppe would give a safe working load of 250kg. Find the breaking stress bs and safe working load swl of a 6x24. A rope s tensile strength is the measure of a brand new rope s breaking point tested under strict laboratory controlled conditions.

When it comes to ratchet straps winch straps and just about any other type of strap in the cargo industry the words working load limit wll and breaking or break strength are commonly seen. In general we recommend the use of a 6 x 26ws in any application where a 6 x 25f is used. Wire rope breaking strain guide posted on 4th april 2017 29th july 2020 by ropeservices wire rope is designed to be an incredibly strong and sturdy piece of equipment that you can safely rely upon for your heavy lifting tasks. D is the diameter of the rope in millimeter the safe working load maybe taken as one sixth 1 6 of the breaking stress.

To calculate the swl you ll need to know the diameter of the rope in inches and apply it to the formula swl d x d x 8. The safe working load is the mass that lifting equipment usually a wire cable can safely hold without fear of breaking. All ropes of the same size grade and core offer somewhat similar minimum breaking force characteristics and weight per foot though they do differ depending on the construction type and materials used. Every piece of webbing buckle ratchet and end hardware has its own number associated with both its wll and break strength.

The safe working limit of a rope is calculated by dividing the minimum breaking strain by a safety factor. 500 divided by 500 as constant in formula for ropes made out of wires.