330 Stainless Steel Machinability

Hot working of grade 330 stainless steel can be performed at 1149 to 1177 c 2100 to 2150 f.

330 stainless steel machinability. 418 greek ascoloy approximate surf. This alloy also possesses great resistance to stress corrosion cracking and sigma phase formation. Rigid mounts sulfurized lubricants positive feeds and slow speeds are recommended for machining grade 330 stainless steel. In the annealed condition it has.

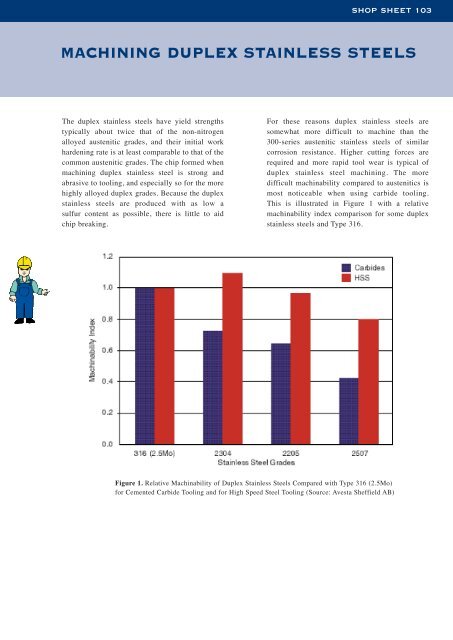

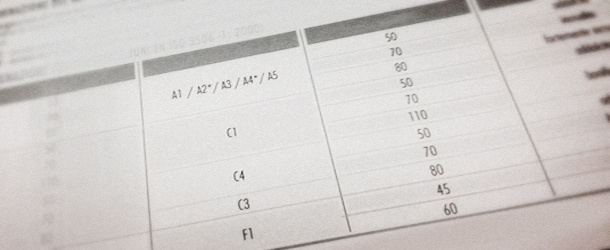

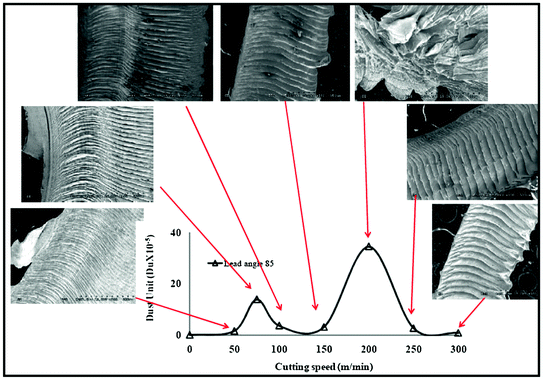

The more difficult machinability compared to austenitics is most noticeable when using carbide tooling. This is illustrated in figure 1with a relative machinability index comparison for some duplex stainless steels and type 316. Incoloy alloy 330 alloy 330 uns n08330 specifications. The american iron and steel institute aisi determined the machinability ratings for a wide variety of materials.

Stainless steel 330 chemical analysis c carbon 0 08max3 mn manganese 2 00 max p phosphorus 0 030 max s sulfur 0 030 max si silicon 1 00 1 50 cr chromium 18 00 20 00 ni nickel 34 0. Note the higher machinability rating of the lean duplex stainless steel s32101 compared. When required the suggested full. Forming at room temperature is suggested whenever possible.

330 347 403 410 416 ann 416 h t. Hot working of grade 330 stainless steel can be performed at 1149 to 1177 c 2100 to 2150 f. It is often used in. This grade is comprised of approximately 36 nickel giving it excellent high temperature oxidation resistance up to 2200 o f.

Ra330 is worked by forming and machining procedures similar to those used with the austenitic stainless steels or nickel chromium alloys. The aisi then arbitrarily assigned 160 brinell b 1112 steel a machinability rating of 100. Rigid mounts sulfurized lubricants positive feeds and slow speeds are recommended for machining grade 330 stainless steel. Grade 330 stainless steel can be welded using gaw techniques.

Grade 330 stainless steel. Grade 330 stainless steel can be welded using gaw techniques. 70 55 150 80 70 70 60 60 60 50 60 60 60 45 60 95 95 150 85 96 relative speed based on b 1112 as 100 40 28 75 43 40 40 36 36 22 36 36 36 20 36 54 54 75 50 50 50. Heat treatment is not necessary after most forming or welding operations.